Rectifiers

Industrial

Rectifiers/Battery Chargers

Rectifiers/Battery Chargers

CBM

CBM

The Microprocessor Battery Rectifier/Charger, CBM series, is an equipment for industrial use, thyristor type, with microprocessor control and supervision.

The main function of the CBM is to charge batteries that feed critical systems operated in direct current.

These systems are present in several industry segments such as: pulp and paper, refineries and oil platforms, mining, steel industry, railways, power generation and distribution among others, whose processes cannot suffer power supply interruptions. As an example: instrumentation and control systems, telecommunications and equipment such as PLC's, relays, high-voltage protection circuit breakers, etc.

Thyristor Systems

- From 24 to 400 Vdc;

- Microprocessed Supervision and remote control;

- Standard RS-232 interface with MODBUS-RTU;

- Optional interfaces - PROFIBUS, DEVICENET, SNMP, IEC61850 or DNP-3;

- From 15 to 2,500 A;

- Protection degree IP-21 to IP-55;

- Memorized event log;

- Other communication protocols or protection degree, under consultation.

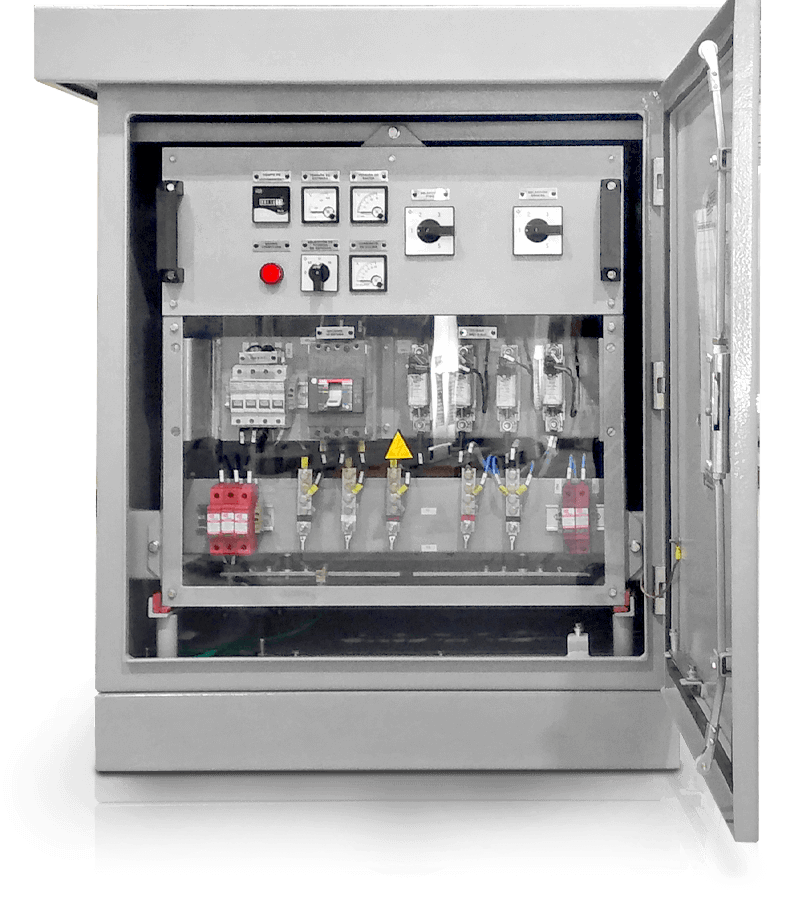

The battery charger is basically composed of an input transformer, with a thyristor rectifier bridge, output filter, microprocessor control and supervisory circuits, and input and output protection devices for the battery and consumer.

With AC mains present, the Battery Charger converts AC mains voltage to DC voltage to charge the battery and supply power to the consumer. In the absence of the AC grid, the battery acts as an alternative power source and powers the consumer without interruption.

The CBM continuously monitors the battery and adjusts the battery output voltage and current limits according to its state of charge, and can operate with automotive or stationary batteries, lead acid or alkaline, vented (open) or valve-regulated (sealed). In emergency situations, it can operate without batteries, behaving as a continuous current power supply.

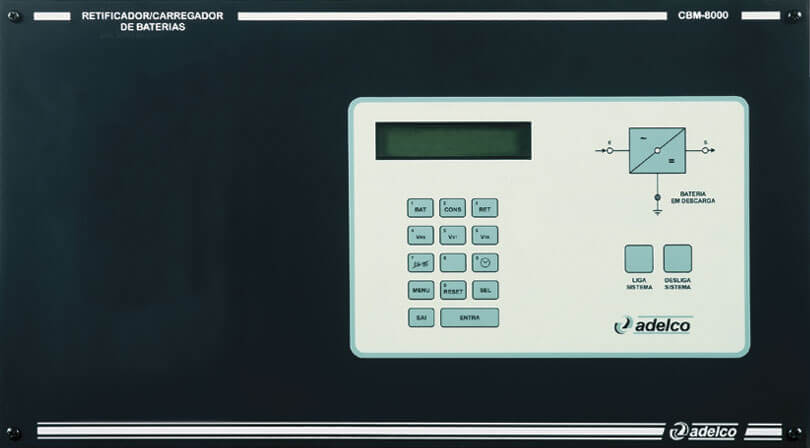

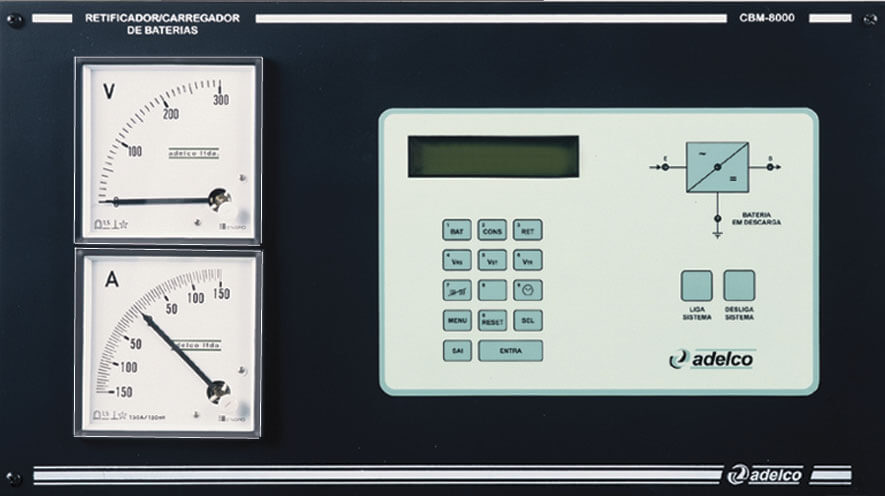

Control panel

- Standard - liquid crystal display, functional membrane keypad and synoptic;

- Customized - according to the client's needs.

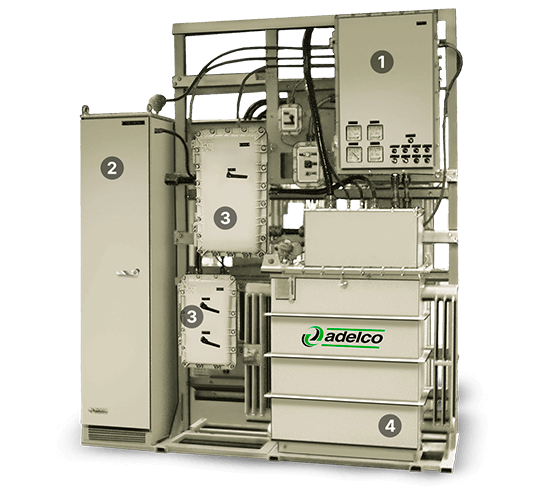

Rectifier / Battery Charger for Hazardous Areas

Hazardous Area Systems

- Ex-d explosion-proof;

- Ex-o oil-filled;

- Ex-n non-sparking;

- Ex-p pressurized;

- Combined systems.

1- Rectifier control and supervision Ex-d / 2- Battery Cabinet IP-56 / 3- Circuit Breakers Ex-d / 4- Transformer Rectifier Controller Ex-o

Industrial Rectifiers

Industrial Rectifiers

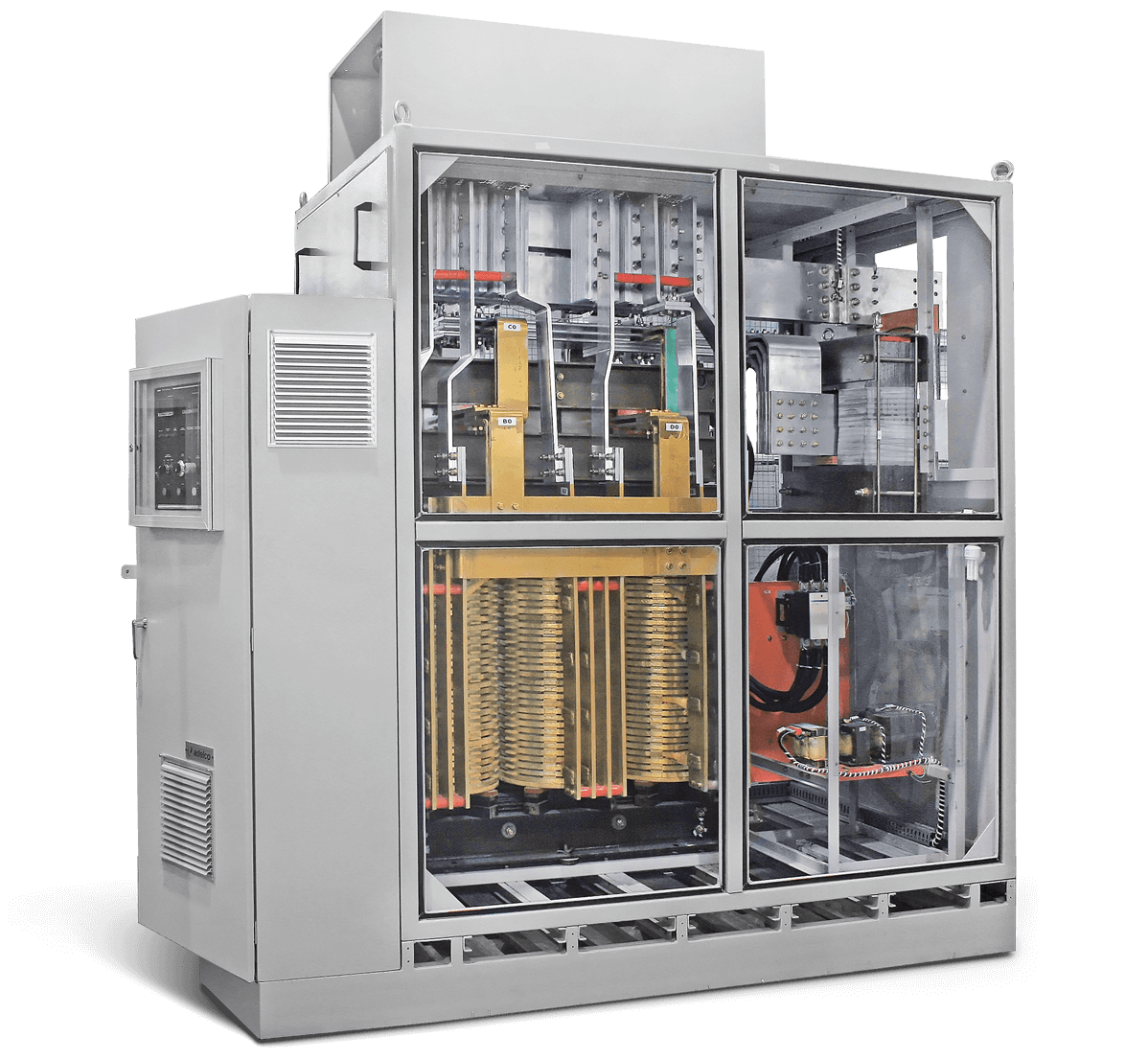

ERD

ERD

The ERD-2000 rectifier is a modern A.C. to D.C. power converter, which features good regulation and high performance. Its versatility makes it applicable to the most diverse industrial processes, such as: electroplating, anodizing, electrolysis, battery recharging and load testing, powering signaling systems, etc.

The rectifier can be operated in local or remote mode, and in remote mode the operation commands and output adjustment are made through dry contacts and 4 to 20mA analog signal, respectively.

The ERD-2000 operates in two distinct modes: local and remote, and can regulate the output in constant voltage or constant current mode.

The commands to turn the rectifier on, off, and reset it are executed through push buttons, the output voltage or current adjustment is made through a multiturn potentiometer, the operation and regulation modes through a switch, and the output voltage and current measurements are given through digital instruments.

In the remote mode, the rectifier receives the commands "start" and "off" through dry contact sensor and adjusting the output through analog signal of 4 to 20mA current.

In an emergency, it is possible to stop the process by turning off the rectifier through the "Emergency Off" button.

It has a synoptic panel that allows the operator to perform the functional monitoring of the equipment through LEDs and digital instruments, and operational monitoring through switches and buttonholes.

The rectifier is built with profile in steel sheet 12MSG receiving treatment that meets the environmental conditions or not containing derivatives of sulfur gases, located at the seashore.

Characteristics - Electrical

- Rated Power up to 2.5 MVA;

- Output voltage up to 3.000V;

- Output current up to 20kA;

- Rectification system of 6 or 12 pulses or 24 pulses;

- LC filter for Ripple attenuation;

- Microprocessed Supervision with serial interface RS232 or 485';

- Interface for communication with CLP.

Characteristics - Mechanical

- Built in metal enclosure;

- Electronics compartment with Protection Degree IP-54;

- Specific painting for every type of environment;

- Customized according to the characteristics of use and space available.

Refrigeration

- Forced air or water cooling for use in harsh environments.

- Autonomous water cooling systems;

- Industrial rectifiers - DC Bus.

Applications

- Train, Subway;

- Repair Shops;

- Conveyor bridges;

- Engines;

- Powering Plasma Generator Devices.

Rectifiers for Electrochemical Processes

Rectifiers for Electrochemical Processes

Applications:

- Electrodeposition of metals;

- Electrolytic cleaning;

- Electropolishing;

- Anodizing, Electrophoretic Painting (KTL);

- Mining;

- Hypochlorite Generator;

- Hydrogen Generator.

Industrial Rectifiers for

Industrial Rectifiers for

Electrodeposition

Electrodeposition

High Frequency Switched

Linear:

- Microprocessed;

- Liquid crystal display;

- Ripple < 1%;

- Interface for communication with supervision;

- Power Rate > 0.92.

Constructive:

- Air or water cooling;

- Modular system;

- Paint suitable for harsh environments;

- Control cards protected against corrosion;

- Special project for each application.

Pulsed:

- With or without polarity reversal;

- Adjustable pulse widths.

Modules:

- 6kW - Air cooling;

- 12kW - Water cooling.

Modular system allows increased output power

Rectifiers for Manual or Automatic Cathodic Protection

Rectifiers for Manual or Automatic Cathodic Protection

REP

REP

The rectifiers can also be used for protection of metal surfaces which, when involved by electrolytic means (water or soil), the peripheral atoms pass into the solution in the form of positive ions, thus establishing an ionic current that causes corrosion.

RECTIFIERS FOR CATHODIC PROTECTION provide the current required to promote balance of potential structureelectrolyte, thus preventing the oxidation reaction. They are projected to operate in aggressive environments and high salinity.

Can be manual or automatic, and in manual model the current is adjusted by TAPs in the transformer (5 coarse and 5 fine), while the in automatic model the output current is adjusted according to the voltage generated by an external reference electrode.

Characteristics

- Manual with TAP's or Automatic;

- Cooling - Air or Oil;

- Single or Multiple Output;

- Direct Potential, Current and Voltage;

- Protection Degree IP-23 to IP-56;

- Standard - Petrobras N-2608