Transformers

Reactors

Dry Transformers

Dry Transformers

Low Voltage

TRB

Low Voltage

TRB

TRB - Single-phase or Three-phase

Transformers are static devices with two or more windings, which transform a voltage and current system into another voltage and current system, both alternating, of generally different values and the same frequency. They are equipment that transmit electrical power.

ADELCO low-voltage transformers can be supplied in the most varied voltages, according to the client's needs, in voltage classes equal to or lower than 1.1 kV.

Features:

- Powers up to 5 MVA;

- Insulation class up to 1.1 kV;

- Winding impregnated or encapsulated in epoxy resin;

- High yield (energy consumption savings);

- Low noise level;

- Maintenance-free;

- With or without protective metal box;

- Protection Degree IP-00 to IP-65;

- Natural or forced cooling (up to 40%);

- Permanent specialized technical assistance;

- According to norms ABNT NBR 5356-11, IEC 60076-11 or equivalent.

Applications:

- Lighting;

- Auxiliary Services;

- Rated Power;

- Distribution;

- Electric Ovens;

- Offshore Platform;

- Rectification;

- Electric Traction.

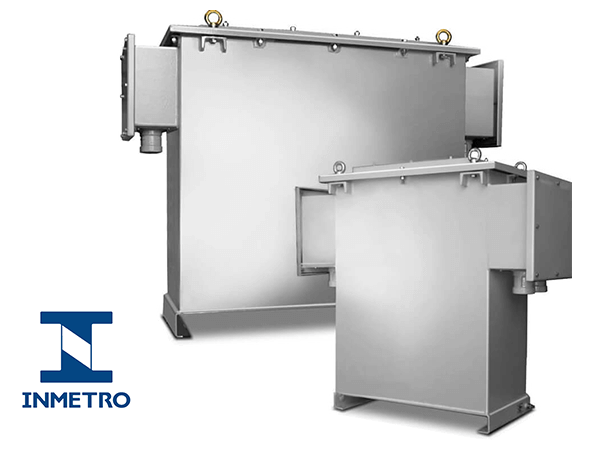

Dry Type Transformers - Low Voltage - Classified Areas

TR-Ex - Single-phase or Three-phase

- Classified Areas - Potentially Explosive Atmospheres (Zone 2);

- Windings encapsulated in epoxy resin, molded;

- Power 5, 10 ,15, 30 and 45 kVA;

- Primary voltage 480 Vac;

- Secondary voltage 208/120, 220/110, 240/120 or 220/127 Vac;

- Frequency 60 Hz;

- Thermal class F;

- Temperature rise 55°C;

- Protection Degree IP-55;

- Certificação UL e INMETRO – UL-BR 12.0297X.

Dry Type Transformers - Low Voltage - Ultra Insulated

TR-HI - Single-phase or Three-phase

Ultra Isolation transformers are electromagnetic devices that decouple electronic instrumentation noise control in existing manufacturing lines. Thus the sensitive instrumentation is isolated from noise.

These characteristics are obtained benefiting the construction of the transformer in order to:

- Get yourself a maximum rejection of common mode noise;

- Minimize the noise-transverse mode, which results in common mode noise between the winding and ground;

- Reduce to the maximum electromagnetic noise emanating from the transformer.

Dry Transformer

Dry Transformer

Medium Voltage

TRM

Medium Voltage

TRM

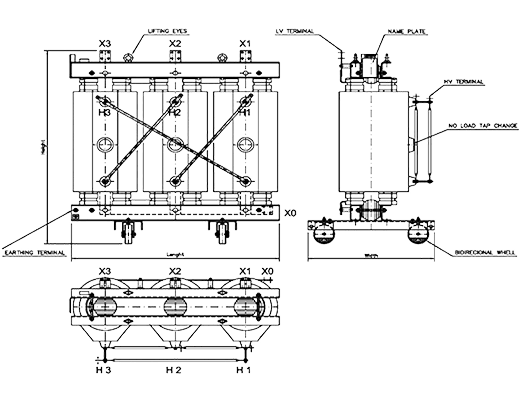

TRM - Single-phase or Three-phase

Transformers are static devices with two or more windings, which transform a voltage and current system into another voltage and current system, both alternating, of generally different values and the same frequency. They are equipment that transmit electrical power.

ADELCO medium voltage transformers can be supplied in the most varied voltages, according to the client's needs, in voltage classes above 1.1 kV and up to 36.2 kV.

Customized Transformers (Flexible and Configurable Designs)

Features:

- Power up to 15 MVA;

- Up to 36.2 kV insulation class;

- Encapsulated and/or vacuum molded epoxy resin windings;

- State-of-the-art resin conjugated system, containing high thermal, mechanical, dielectric, and flame retardant (E1-C1- F1) resistance;

- High yield (energy consumption savings);

- Low noise level;

- Maintenance-free;

- With or without protective metal box;

- Protection Degree IP-00 to IP-65;

- Natural or forced cooling (up to 40%);

- Permanent specialized technical assistance;

- According to norms ABNT NBR 5356-11, IEC 60076-11 or equivalent.

Standardized Transformers (Standard and Non-Configurable Designs)

Features:

- Powers from 30 kVA to 3,000 kVA;

- 15 kV insulation class;

- Primary voltages 14.4 / 14.1 / 13.8 / 13.5 / 13.2 kV;

- Secondary voltages 220/127 to 480/277 V;

- Protection Degree IP-00;

- Natural cooling;

- Temperature class F (155 °C);

- Temperature rise 100 °C;

- Nominal frequency 60 Hz;

- Angular displacement Dyn1;

- PT 100 temperature sensor in the central BT stage;

- ABNT NBR 5356-11.

Main Advantages of Dry Transformers:

- Self-extinguishing and do not release toxic gases;

- No risk of contamination from oil leakage;

- Safety in case of explosion by no fire spread in the event of fire;

- Free of partial discharges;

- Low noise level;

- Possibility to adapt to forced ventilation system, increasing its rated capacity by 40%;

- Maintenance-free;

- No special conditions required for installation;

- Robust construction, support an inclination of fifteen degrees to the horizontal plane;

- Manufactured of materials suitable for use at high temperatures;

- Reduction in raw material used and final dimensions.

- Manufactured of materials suitable for use at high temperatures;

- Simplified temperature monitoring by PT-100/monitor.

- Meets the NBR 14039 standard regarding the installation of transformers inside buildings and constructions.

Applications

- Rated Power;

- Distribution;

- Electric Ovens;

- Offshore Platform;

- Rectification;

- Electric Traction;

- Static Excitation of Generators;

- Coumpound;

- Grounding.

Reator Air Core

Reator Air Core

RNA

RNA

ADELCO reactors, designed in compliance with ABNT, IEC and ANSI standards, are manufactured for internal installation in switching cabinets and shielded cubicles or, when necessary for outdoor installation. The coils are made with one or more high conductivity aluminum or copper conductor, with one or more layers, an increase of temperature corresponding to the class of insulation and reinforced with special encapsulation ensuring high mechanical rigidity.

Air core

- Encapsulated in

fiberglass and epoxy resin;

- Low / Medium / High Voltage (up to 525 kV);

- Protection Degree IP-00 to IP-55.

Applications

- Short circuit limitation;

- Harmonic filter;

- Limitation of inrush current;

- Reactive Compensation;

- Offshore;

- Railway;

- Straightening;

- Shunt;

- Grounding.

Reactor Iron Core

Reactor Iron Core

RNF

RNF

ADELCO iron core reactors, designed in compliance with ABNT, IEC and ANSI standards, are manufactured for sheltered installation in substations, distribution boards and armored cubicles or, when necessary, for external installation in boxes with adequate protection degree. They are robust equipment with copper or aluminum windings and with an insulation system suitable for each application.

Center of Iron

- Vacuum impregnation process, (VPI);

- Low / Medium voltage (up to 36.2 kV);

- Spatial distribution of air gap.

- Protection Degree IP-00 to IP-55

Applications

- Reactive Compensation;

- Current Switching / Limiting;

- Filters for DC;

- Engine start-up;

- Desintonized filter;

- Offshore;

- Railway.

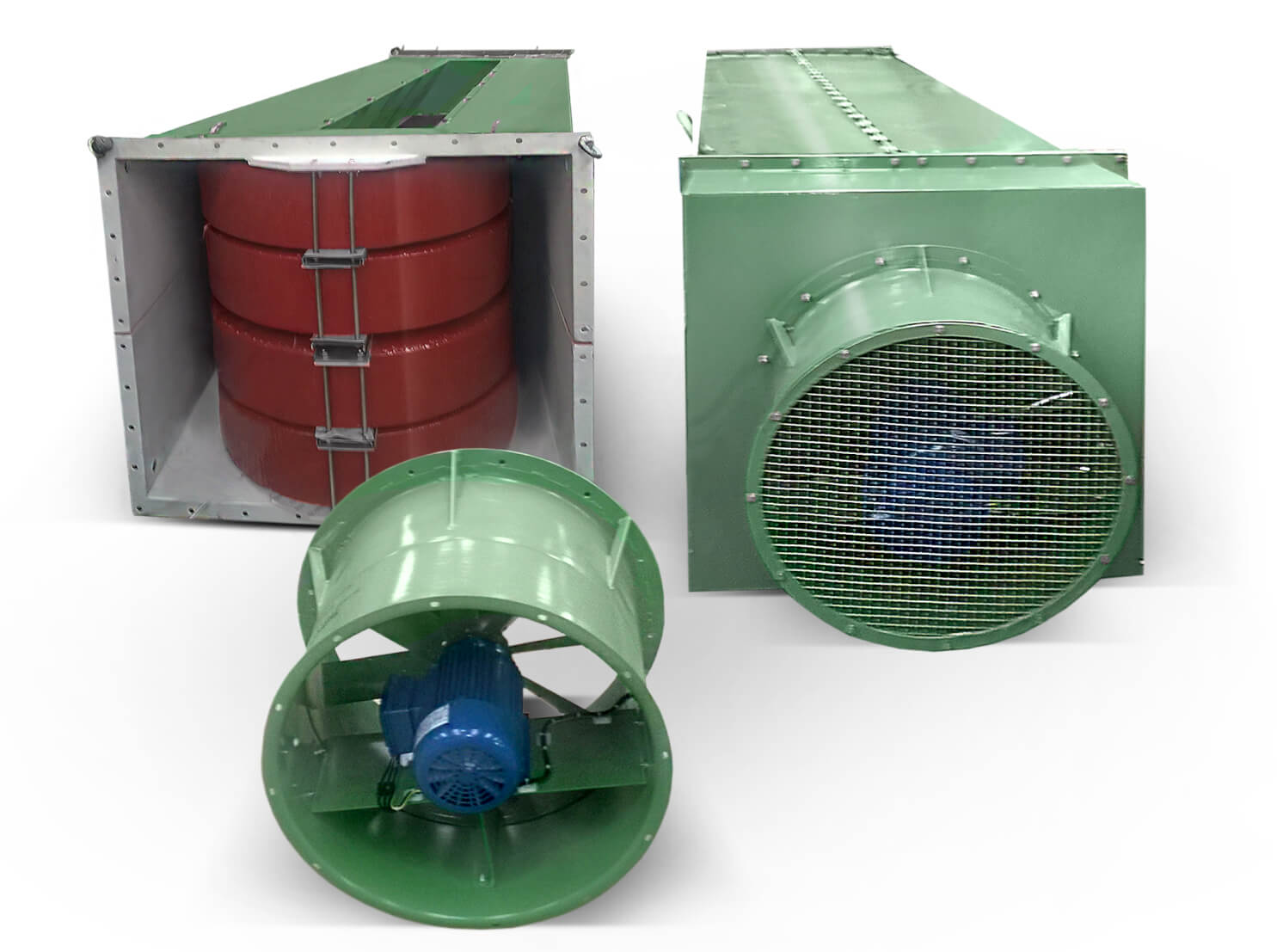

Magnetic Separator Coils

Magnetic Separator Coils

The application of high intensity magnetic separators is extremely important in ore separation.

Designed to work in wet or dry processes, these separators are based on the difference in magnetic susceptibility between magnetic and non-magnetic materials, enabling their separation. This process allows the segregated material to be reused as an intermediate product, making the process more efficient.

Separator boxes can be assembled in stainless steel or carbon steel, according to each customer's needs.

The internal coils generate a high magnetic field gradient and are composed of aluminum wires insulated with material with high dielectric strength, mechanical flexibility and high thermal resistance (thermal class "H" - maximum working temperature 180 °C). The coils are cooled by fans coupled to the end of the box, thus ensuring the thermal dissipation of the set.